9002GA(9600Q)/9002GB(9600Q)Filled Heat Cure Epoxy Casting Resin System for automotive ignition coil

Description

l 9002GA(9600Q)/9002GB(9600Q) is a filled, heat cure two part epoxy casting resin system.

l 9002GA(9600Q)/9002GB(9600Q) is recommended for casting of ignition coil for automobile.

l 9002GA(9600Q)/9002GB(9600Q) offers low filler sedimentation and good thermal resistance.

l Excellent and electrical properties.

Application

(Mix) Prior to mix, agitate homogeneously each materials, 9002GA(9600Q) and 9002GB(9600Q)B, in the container.

Then mix 9002GA(9600Q) and 9002GB(9600Q) completely at proper mix ratio.

(Cure) Recommended cure:

2.5 hours at 90℃ plus 2.5 hours at 130℃

Storage and handling

Keep each materials in closed package in cool and dark place.

9002GA(9600Q)/9002GB(9600Q) resin system may cause skin irritation, void skin contract.

If contract occurs, wash with soap and water at first opportunity.

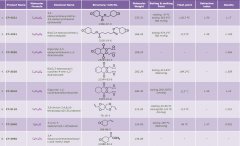

General Properties of 9002GA(9600Q)/9002GB(9600Q)

|

Test Item |

Unit |

condition |

Typical Values |

|

|

A Liquid |

B Liquid |

|||

|

Each Properties |

||||

|

Apperance |

—— |

25℃ |

Black Or White Paste |

Light yellow transparent Liquid |

|

Ingredient |

—— |

—— |

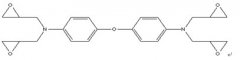

Epoxy resin |

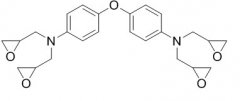

Acid anhydride |

|

Specific Gravity |

—— |

25℃ |

1.83±0.05 |

1.20±0.05 |

|

Viscosity |

Pa·s |

25℃ |

>500 |

0.03~0.12 |

|

The mixture Properites |

||||

|

Mix Ratio by weight |

—— |

—— |

100/28 |

|

|

Specific Gravity |

—— |

25℃ |

1.64±0.05 |

|

|

Initial Viscosity |

Pa·s |

25℃ |

3.0~8.0 |

|

|

Work life (The time until double of initial viscosity) |

h |

60℃ |

>2 |

|

|

Gelation time (Testing tube Method 10g) |

sec |

140℃ |

300~360 |

|

|

Cured Properites |

||||

|

Cure condition |

℃/h |

—— |

90/2.5+130/2.5 |

|

|

Color |

—— |

25℃ |

Pale yellow |

|

|

Hardness(Shore D) |

—— |

25℃ |

90±5 |

|

|

Bending strength |

N/mm2 |

25℃ |

>130 |

|

|

Bending modulus |

N/mm2 |

25℃ |

5800~7800 |

|

|

Glass transition temperature |

℃ |

—— |

>125 |

|

|

Coefficient of linear expansion |

×10-5K-1 |

—— |

4.5±0.5 |

|

|

Heat deflection temperature |

℃ |

—— |

>128 |

|

|

Boiling water absorption (after 100℃×1h) |

% |

—— |

<0.2 |

|

|

Dielectric strength |

MV/m |

25℃ |

>25 |

|

|

Volume resistivity (DC500V) |

MΩ·m |

25℃ |

>1×107 |

|

|

100℃ |

>1×106 |

|||

|

(50Hz) |

—— |

25℃ |

≦4.1 |

|

|

100℃ |

≦4.4 |

|||

|

Dissipation factor (50Hz) |

% |

25℃ |

≦1.0 |

|

|

100℃ |

≦2.0 |

|||

Note: Test method is based on JIS C 2105.

购买请联系:王强(先生):13771380144

QQ:1018897670

E-Mail:epoxycn888@gmail.com